Widely Used PP Jumbo Super Sacks Big Bags 1 ton bulk bag for construction

Item specifics

- Safety Factor

- 5:1

- Loading Weight

- 800kg - 2000kg

- Brand Name

- DAPOLY

- Color

- White /Yellow/Blue

- Size

- Customized at buyer

- Thickness

- 140g/m2 - 200g/m2

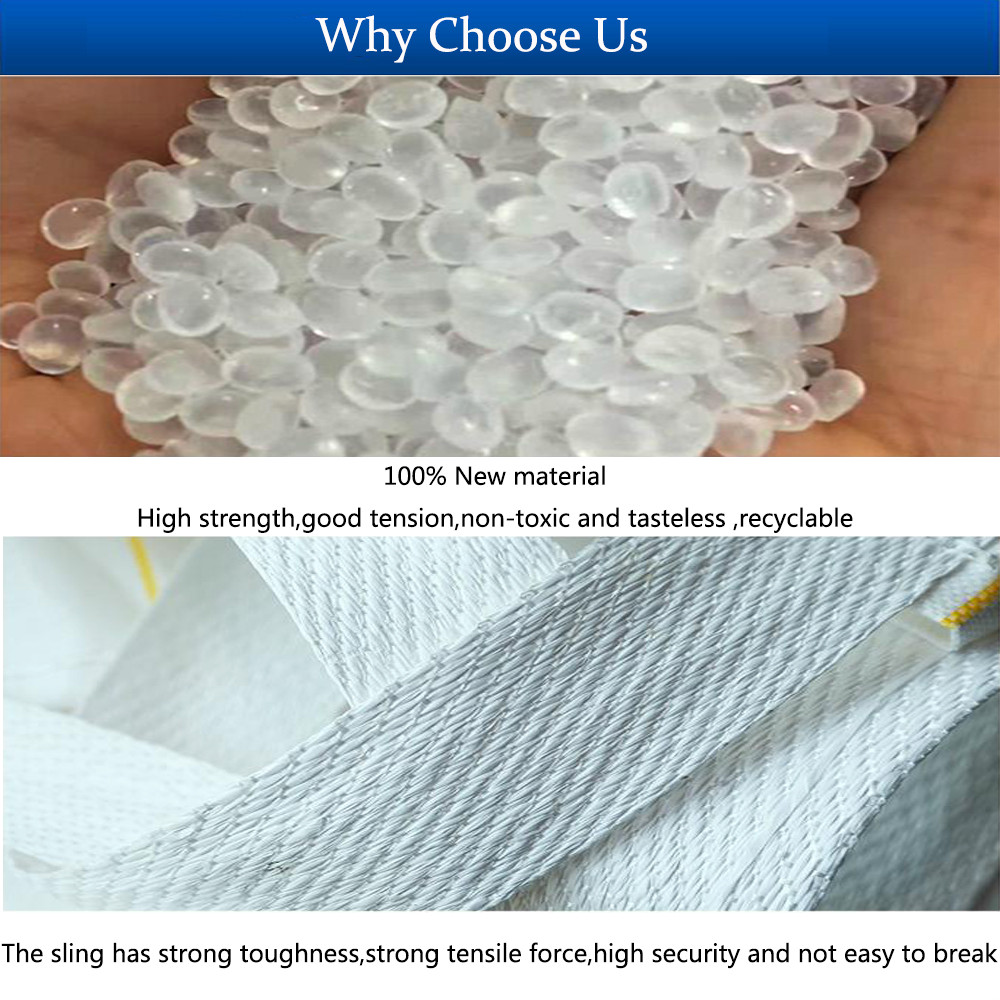

- Material

- 100% Virgin Polypropylene

- Top Option (Filling)

- Top open/Top Fill Spout/Top Skirt

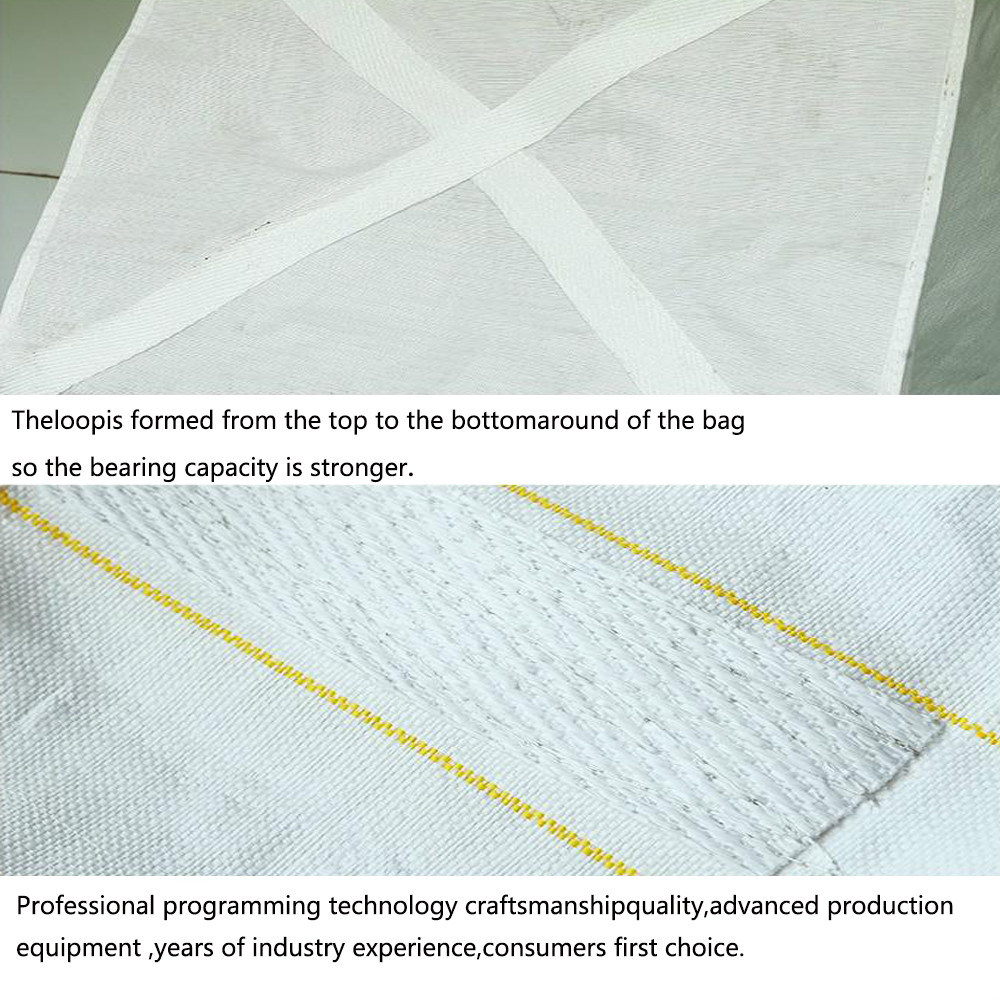

- Loop Option (Lifting)

- Fully Belted Loop

- Bottom Option (Discharge)

- Flat bottom/With Spout Safety Factor:5:1

Review

Description

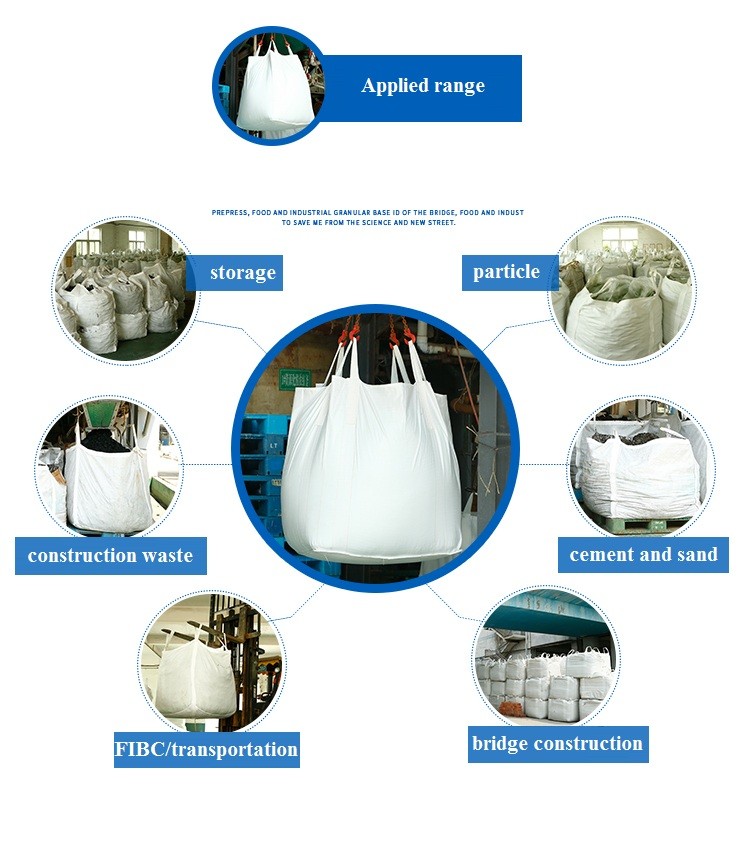

A big bag or FIBC (Flexible Intermediate Bulk Container) is a large woven bag designed to carry bulk materials.

They differ from RIBCs, rigid intermediate bulk containers, by having flexible walls and tend to be used for dry bulk solids; however, recent developments in bag liners and big bag manufacturing allow the big bag to be used in other applications as well.

The growth in big bag usage has been constant over the last 10 years. Approximately 100 million bags are used annually with an average annual growth rate of around 12% per year. This growth is projected to continue due to the many advantages big bags provide over other containers, like paper bags, rigid IBCs, fiber, plastic, or metal drums.

|

Fabric specification |

|||||

|

Standard Test Item |

Body Fabric |

Inlet Spout Outlet Spout |

|||

≤1000 kg | ≤2000 kg |

≤3000 kg |

|||

Tensile strength N/50mm | Lengthways | ≥1470 | ≥1646 | ≥1960 | ≥828 |

Crosswise | ≥1470 | ≥1646 | ≥1960 | ||

Elongation δ % | Lengthways | ≤40 | ≤40 | ||

Crosswise | |||||

Heat resistance | No abnormality | ||||

Cold resistance | No abnormality | ||||

loops specification | |||||

Tensile strength F N/Piece | F≥W/n x 6 | ||||

Elongation δ % | When the load is 30% of the tensile strength F, the elongation is <25 | ||||

|

F: Tensile strength N/piece W:Maximum load N n: Number of loop 2n for ring connection 6: Safety factor |

|||||